“Recycling lithium-ion batteries is a complex and inherently risky process.” — Brian O’Connor, NFPA

Recently, a lithium-ion battery-powered Cybertruck exploded outside of the Trump International Hotel in Las Vegas. It wasn’t the Li-ion batteries that exploded, though. It was a cargo of fuel and fireworks. In the case of the Li-ion battery recycling plant in Fredericktown, a small Missouri town about an hour-and-a half southwest of St. Louis, that burned, it was the batteries. Authorities evacuated people living downwind of the fire and there was a massive fish kill. Fortunately, there were no deaths or injuries.

A History of Fires

If you travel by air, you already know that airlines prohibit lithium-ion batteries from your checked baggage. The FAA reports that in 2024 alone, there were 62 incidents involving smoke, fire, or intense heat, and that their list “should not be considered complete.” Fire departments are increasingly tracking lithium-ion battery fires as a separate category. Massachusetts, for instance, is seeing lithium-ion battery fires at a rate of almost 10 per month. About a third involved laptops, cell phones, tablets and other electronic devices. Almost 20% involved micromobility devices like scooters, e-bikes, and hoverboards. Battery-powered tools were another leading cause.

Most of the concern is directed at consumer products that take advantage of lithium-ion batteries, and their end-users. There are many videos available to show just how dramatic a lithium-ion battery fire can be. Figure 1, for example, is an image captured from a Consumer Product Safety Commission video, warning consumers of the dangers of lithium-ion batteries.

Figure 1. Still from “Battery Fire!” produced by the U.S. Consumer Product Safety Commission. See the full video at https://www.youtube.com/watch?v=_ds2X8csUj4

But it is not just consumer product fires that are the issue. Recent compilations include a few large-scale fires ignited by lithium-ion batteries. They occurred in many segments of the lithium-ion battery lifecycle:

- Superior Battery, Morris, Illinois. June 29, 2021. Batteries in storage for future use

- Felicity Ace, Atlantic Ocean. February 16, 2022. Batteries installed in electric vehicles being shipped.

- Vistra Energy Facility, Moss Landing, California. February 13, 2022. Batteries in use at solar and wind energy storage facility.

- Shoreway Environmental Center, San Carlos, California. September 7, 2016. Improperly disposed battery in ordinary solid waste.

- Royal Waste Service, Jamaica, New York. March 16, 2018. Improperly disposed battery in ordinary solid waste.

And now

- Critical Mineral Recovery, Fredericktown, Missouri. October 30, 2024. Fire at lithium-ion battery recycling plant.

I don’t include the fire at the Ancell battery manufacturing plant in Hwaseong, South Korea on June 24, 2024, in the list above. It is not because it wasn’t horrific—23 people died—but because that factory was manufacturing lithium metal batteries, not lithium-ion batteries.

Why Are Li-Ion Batteries So Hazardous?

There have been safety issues with lithium-ion batteries since they were first invented in the 1970s. One problem is that the electrolytes, typically a mixture of ethylene carbonate and other alkyl carbonates, are flammable liquids. Another is the hexafluorophosphate ions in the battery, which when exposed to water decomposes to form hydrogen fluoride and phosphoryl fluoride ions, both of which are toxic.

The gravest hazard, however, is thermal runaway. Thermal runaway occurs when a battery cell short circuits and begins to heat up uncontrollably. Many things can cause a lithium-ion battery to short circuit: failure of the separator between the anode and cathode from poor manufacturing or from physical damage during use, overcharging or charging too rapidly (which causes lithium metal dendrites to form which puncture the separator), or temperature extremes—too hot or too cold.

NFPA 800

Early in December 2024, the NFPA Standards Council met in Charleston, South Carolina to consider, among other things, whether the National Fire Protection Association should develop a new standard, NFPA 800 Battery Safety Code. The purpose of the code is to provide minimum requirements for mitigating fire, explosion, electrical, life safety, and property protection throughout the lifecycle of batteries. Specifically, the proposed standard will apply to manufacturing, assembly, transportation, storage, installation, use, operation, recycling, disposal, and reuse of batteries.

The NFPA solicited comments, either in support or opposition to developing such a standard, They were due by July 12, 2024. The NFPA received 75 notes; 70 were in favor, and 5 (including one from Honeywell and one from Tesla) were in opposition.

The committee working on the proposal estimated that it will take about three years to develop the standard. Given the breadth of the code, three years seems optimistic. In any case, it cannot be too soon. The fire at Fredericktown has already happened. There are likely to be other fires.

Process Safety At A Lithium-Ion Battery Recycling Plant

As the use of lithium-ion batteries grows, recycling those batteries will be key to fulfilling their promise of green energy. While there is not likely to be much effort, at least initially, in collecting and recycling the alkyl carbonates that comprise the battery electrolyte, or the plastic housings that encase the battery, the batteries are a rich source of lithium, cobalt, manganese, and nickel, as well as aluminum and copper.

Separating and purifying these materials calls on the talents of process engineers, and where there is processing, there are process safety issues.

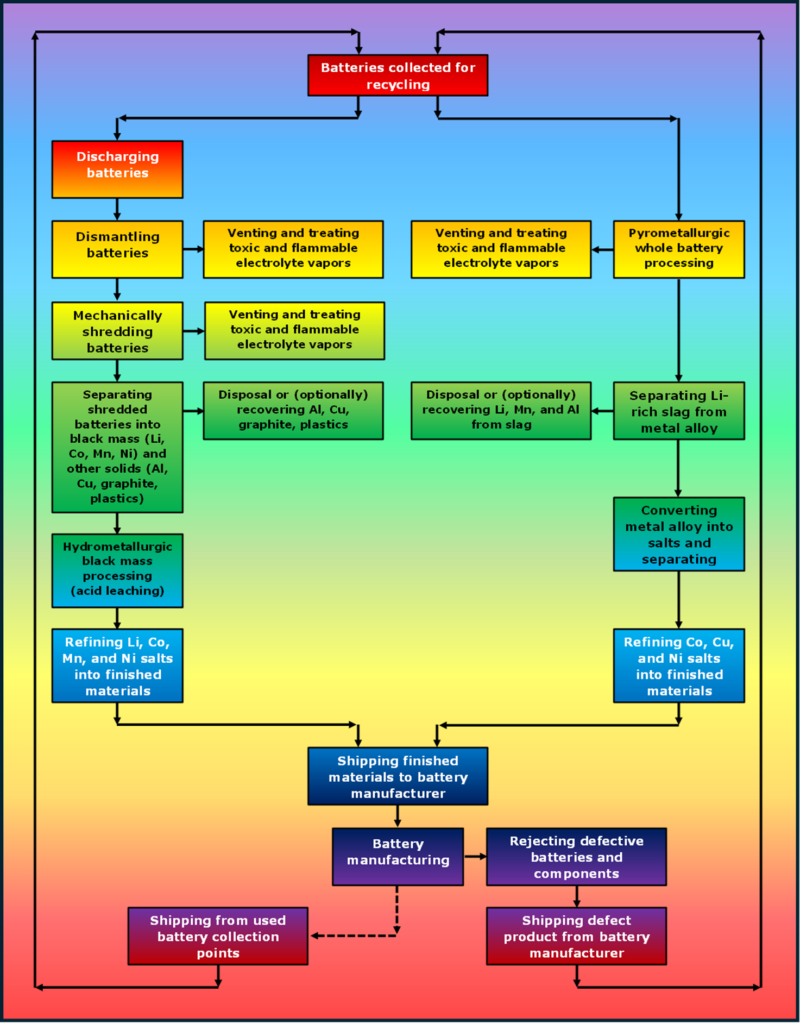

Figure 2 shows a generic block flow diagram of the lithium-ion battery recycling processes. Every block in the diagram has its own process safety concerns.

Figure 2. Lithium-ion battery recycling – a general block flow diagram

Here is a brief listing of some of those process safety concerns:

- Collecting batteries for recycling: batteries to be recycled, whether used or defects from manufacturing processes, are subject to the kind of damage that leads to thermal runaways and fires. Because the battery cells are encased, it is difficult for water to get to a fire that starts at the core of the battery, even from an advanced, state-of-the-art fire suppression system. Transport and storage of batteries to be recycled will require segregation, something akin to storing and shipping explosives.

- Venting and treating flammable and toxic vapors: The alkyl carbonates that comprise the battery electrolyte are flammable, and likely require thermal oxidation. Likewise, hexafluorophosphate, and resulting hydrogen fluoride and phosphoryl fluoride are toxic, and will need to be handled accordingly.

- Pulverizing metals: The particle size in black mass—the mixture of lithium, cobalt, manganese, nickel and other metals used in a lithium-ion batteries—typically means that black mass is not a combustible dust. However, fines from the size reduction process can pose combustible dust hazards.

- Isolation of metal salts: Depending on the recovery process—and every plant has its own—lithium-ion battery recyclers use almost every mineral acid known to chemistry. This includes hydrochloric acid, nitric acid, sulfuric acid, and phosphoric acid. Each has its own process safety concerns.

A Place for Lithium-Ion Battery Recycling to Grow

The demand for lithium-ion battery recycling is going to grow as the demand for lithium-ion batteries grows, although it will lag that growth by about a decade, since a decade is about the useful life of a lithium-ion battery. The technology of lithium-ion batteries is going to evolve, meaning that the technology of lithium-ion battery recycling will also have to evolve. The challenge for recycling facilities is keeping up, not with just one evolutionary path, but all of them.

The people of Fredericktown, Missouri were thrilled when Critical Mineral Recovery came to town. It meant jobs and economic development. That goodwill went up in smoke, however, when the plant burned on October 30. A massive fishkill, evacuations, potential exposure to hydrogen fluoride; most people hadn’t bargained for any of these things when they welcomed the plant to town. Now, many aren’t sure they want the plant to reopen.

If the plant doesn’t reopen in Fredericktown, it will open somewhere else, which would be a shame for the people of Fredericktown. Regardless of where it opens, though, the owners will need to take into account all of the process safety lessons learned. Any of us who get involved in this industry will need to work hard to make Fredericktown the exception, not the rule.