“You may reasonably expect a man to walk a tightrope safely for ten minutes; it would be unreasonable to do so without accident for two hundred years.” — Bertrand Russell

Many of us face a dilemma when it comes to fall hazards. Particularly when it comes to maintenance. The hazards are unavoidable, the consequences of an incident can be tragic, and the only layer of protection available to us is some form of personal protective equipment.

We can expect that a risk analysis of the task will show that the risk is too high to meet our risk tolerance criteria. What do we do?

The High Risk of Falls

There are two factors that contribute to the risk of a fall. The first is the likelihood of falling. The second is the consequence severity of the fall.

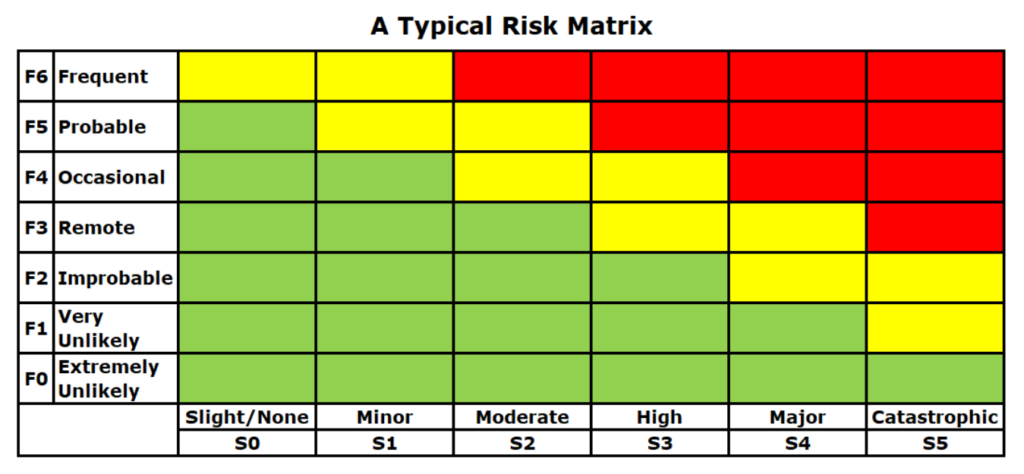

A typical risk matrix divides likelihood into categories. The best risk matrices define the categories in terms of quantitative frequencies separated by orders of magnitude: once a year, once a decade, once a century, once a millennium, and so on.

Then the risk matrix layers in consequence severity categories. Some risk matrices only go as far as labelling the categories, leaving it to each user to assign meaning to the labels. The best risk matrices take care to define the consequence severity categories, using examples that clearly separate them by orders of magnitude.

A category that includes a single fatality is often the second most severe category. (The most severe category being that of multiple fatalities, or more specifically, 10 or more fatalities when we adhere to the order-of-magnitude rule.) In our illustration, a fatality would be MAJOR‑S4. A permanently disabling injury is usually in the next most severe category, and then OSHA‑recordable injuries. In our illustration, a permanently disabling injury would be HIGH‑S3 and an OSHA‑recordable injury would be MODERATE‑S2.

If our “typical” risk matrix defines FREQUENT‑F6 as more often than once per year, then a task that results in a fatal fall annually (S4:F6) falls in the red zone, which is risk that is intolerably high. It is not until the frequency is reduced to less than once per century, REMOTE‑F3, that a fatal falling hazard gets to the yellow zone, often known as the As-Low-As-Reasonably-Practicable or ALARP zone. In the ALARP zone, we can apply cost/benefit analysis to risk reduction measures. It is not until the frequency is reduced to less than once per 10,000 years that a fatal falling hazard gets to the green zone, which represents risk that is tolerably low and requires no additional efforts to reduce risk.

When analyzing a task with fall hazards to determine its risk, we need to determine how severe we expect the consequences to be (a fatality, a permanent disabling injury, an OSHA recordable injury, or less) and the frequency at which such a fall would occur.

Consequence Severity of Falls

There is no height that is so high that a fatality is certain. In 1972, Vesna Vulović a flight attendant on JAT Flight 367 survived a fall of over 10 km (6.3 miles, 33,000 feet) without a parachute when an explosion ejected her from the plane. There are other stories of people surviving falls of several kilometers from aircraft. Nonetheless, the height from which we can expect a fall to be fatal is considerably less than 10 km.

On the other hand, there is no height so low that surviving unscathed is guaranteed. Every year the Bureau of Labor Statistics reports on the dozens of workers who died upon falling on a level surface. In 2023, the most recent year for which the BLS has reported data, 140 of the 5,283 work-related fatal injuries were the result of falling on the same level. Nonetheless, we do not expect a fall to be fatal when it is on the same level.

What do we expect?

There is a consensus that a fall from an elevation greater than 9 meters (30 feet) is more likely to result in death than not. For falls from these heights, the severity in our illustration would be MAJOR‑S4.

OSHA requires guard rails or other fall protection systems for elevated levels that are 1.2 meters (4 feet) or more above an adjacent level. This is consistent with the expectation that a fall from this height will result in serious injury. The severity in our illustration would be HIGH‑S3.

We can expect that falls from elevations less than 1.2 meters (4 feet) will have less severe consequences. For a fall from an elevated surface that is less than 1.2 meters (4 feet) above an adjacent level, we can expect an OSHA‑recordable injury. The severity in our illustration would be MODERATE‑S2.

Finally, for falls on a level surface, we can expect no worse than a first-aid injury. The severity in our illustration would be MINOR‑S1. Yes, falls on a level surface may result in a fatality, but our expectation is that the consequences would not be that severe.

You may notice that no elevation leads to the expectation of a fall with a consequence severity of CATASTROPHIC‑S5. That is because we do not expect any fall to result in multiple fatalities. With only rare exceptions, falls kill us one at a time.

Frequency of Falls

It is not enough to know the consequence severity of a fall. To know the risk of the task that leads to the fall, we also have to know the frequency of the falls.

When estimating the frequency of a fall, we begin by estimating the frequency of opportunities. Is the task performed three times a day (a thousand times a year), or once every 10 years? The fewer the opportunities, the lower the frequency of falls, and for a given consequence severity, the lower the risk.

Not every opportunity results in a fall, however. Intuitively, our own experience with being at elevation suggests that one fall per 10 opportunities is too much. How about one fall per 100 opportunities? One fall per 1,000 opportunities?

Consider roofing. The roofing industry employed 135,140 roofers in 2023, while the number of recordable cases for the roofing industry in 2023 was 7,000. Assuming a 6-month construction season (260 days), that roofing injuries are almost entirely from falls (fatal injuries certainly are), and that roofers NEVER use fall protection (which is not true but is not out of line with my own observations), that works out to about one fall per 5,000 daily opportunities.

Given the probability of falling when at elevation – one fall per 5,000 opportunities – and an estimate of the rate of opportunities, we can calculate the frequency of falls for a task. And knowing the height at which the task occurs, we can reckon the consequence severity of the fall. With both frequency and consequence severity in mind, then, we can assess the risk of falling while performing a specific task.

The Risk of Falling – An Example

Imagine a task where a maintenance technician needs to climb a ladder to a pipe rack in order to repair a leaking flange gasket. The pipe rack is twenty feet off the ground. When the maintenance technician is working on the leak, their feet are sixteen feet off the ground. This is a task that is performed about three times per week.

First, what is the consequence severity category? The maintenance technician performs the task at an elevation between 4 feet and 30 feet, meaning that we would expect the consequence severity category in our illustration to be HIGH‑S3.

Second, what is the frequency? This task is performed about three times per week, so there are about 150 opportunities per year. The probability of falling is once per 5,000 opportunities. The frequency of falling while performing this task, then, is 0.03 falls per year. This frequency, 0.03 falls per year, is between 0.01 incidents per year and 0.1 incidents per year. In our illustration, the frequency category would be OCCASIONAL-F4.

The risk, then, would fall on our risk matrix at S3:F4, which is in the yellow, or ALARP, zone. The risk is not intolerably high (in the red zone) but not so low as to be tolerated (in the green zone). On the basis of risk, we need to implement additional measures, as long as they are practicable and cost effective.

(On the basis of regulatory compliance with OSHA’s 29 CFR 1910.28(b), we have to implement fall protection measures, regardless of the risk, because of the height.)

Risk Reduction Measures

There are several types of risk reduction measures for falls. While OSHA approves each of them, they are not each equally reliable. Some have a worse average probability of failure on demand (PFDavg) than others and so do not provide as much risk reduction.

- Harness and lanyard – PFDavg = 0.1.

As with all PPE, a harness and lanyard depend on human action. There should be no credit (PFDavg = 1) if the lanyard is not connected to an adequate anchor (tie-off point), or if the lanyard length cannot arrest the fall before the person hits an object below. - Fall restraint system – PFDavg = 0.1

Fall restraint systems, whether they are vertical lifelines, horizontal lifelines, or fall restraints on an open mezzanine, are other forms of PPE that also depend on human action. Again, there should be no credit (PFDavg = 1) if the restraint line is not connected to an adequate anchor or if the restraint line is to long to prevent the person from falling. - Scaffolding or temporary platform with std guardrail and toeboard – PFDavg = 0.01

OSHA defines a standard guardrail as having a top rail at least ¼” diameter at a height of 42”±3”, a middle rail at least ¼” diameter at a height of 21” (nominal), and capable of withstanding a downward force of at least 200 pounds. However, OSHA does allow screens, mesh, vertical members, or solid panels instead of middle rails, as long openings are not more than 19”. Toeboards must be at least 3½” high with no more than a ¼” gap between the working surface and the toeboard. - Mobile lift – PFDavg = 0.01

This includes scissor lifts and aerial lifts, which OSHA considers a form of scaffolding, and which must be equipped with standard guardrails and toeboards. - Safety net – PFDavg = 0.01

Safety nets must be installed as close as is practical under the working surface but not more than 30 feet under the working surface, and must be able to withstand a 400-pound drop test. Other requirements can be found in 29 CFR 1926.502(c). - Permanent platform with standard guardrail and toeboard – PFDavg = 0.001

The requirements for the standard guardrail and toeboard are the same as the same as for temporary platforms. Permanent installations are generally of sounder construction, so more reliable than temporary installations. Hence the lower PFDavg.

In our example above, using a harness and lanyard tied off to an adequate anchor point lowers the likelihood of a fall by one order of magnitude, landing in S3:F3 of our risk matrix. Better, but still in the yellow, ALARP zone. Using a mobile lift instead lowers the likelihood of a fall by two orders of magnitude, landing in S3:F3 of our risk matrix. That puts the risk is in the green, tolerable zone, meaning there is no need to reduce the risk further.

Is PPE Adequate?

OSHA’s regulations on fall protection are satisfied by PPE, whether a harness and lanyard or a fall restraint system, in cases where fall protection is required. But PPE only provides one order of magnitude in risk reduction. That is only enough when the risk is already low. When the risk is higher, for instance in the case of a tightrope walker performing twice daily over a canyon that is 100 meters deep (S4:F5), PPE alone is not enough to move out of the red, intolerable, zone. Even the additional use of a safety net leaves the risk (S4:F3) in the yellow, ALARP zone. For a high wire act, however, a harness and a safety net may be all that is practicable.

Jobs that require working at height, however, should not be high wire acts.

There Is More To Fall Protection Than PPE

When a task involves working at elevation, OSHA regulations require some form of fall protection. For many, the immediate thought is some form of PPE. That will satisfy OSHA’s requirements, but it is not the only choice. Some choices, such as mobile lifts, are better, safer choices. If the task is performed in a single location with some frequency, a permanent platform with guardrails and toeboards is an even better choice. Make sure that your risk assessments consider all your options and then choose the best one for the situation. When all the risk reduction measures are considered and the risk is still too high, then the option that remains is finding a way to reduce the frequency of the task.