“Restaurant kitchens have grease fires all the time. A little oil on a burner, and you clear out a restaurant without raising too much suspicion or causing too much damage…Still, it’s best not to stick around too long after you’ve set a kitchen on fire.” — Michael Westen, on Burn Notice

It’s hard to get liquids with really high flash points to ignite. As a result, liquids with really high flash points are not regulated very strictly. While hard to ignite, though, liquids with high flash points can still burn. Grease fire, anyone?

What is a really high flash point? Most cooking oils have a flash point of around 600 to 635°F (315 to 335 C). Gasoline, on the other hand, has a flash point of around ‑49°F (‑45 C). (We say “about” because gasoline, like cooking oils, is a mixture of different chemical compounds. We don’t have to say “about” when talking about pure chemicals.) The National Fire Protection Association (NFPA) uses a flash point of 100°F (38.8 C) to distinguish between flammable liquids and combustible liquids. The Globally Harmonized System (GHS) of labeling doesn’t use the term “combustible liquids”; ignitable liquids with a flash point up to 199.4°F (93 C) fall into one of four “Categories.”

What is a flash point? It’s the temperature at which a liquid has a high enough vapor pressure to form an ignitable mixture with air. It’s not the temperature at which a material will spontaneously burst into flames in air. That’s the autoignition temperature (AIT) and a material’s AIT is much higher than its flash point. Anything that will burn has an AIT, but only liquids have flash points.

What Are Class III B Combustible Liquids?

Class III B combustible liquids are what the NFPA calls ignitable liquids with a flash point at or above 200°F (93.3 C). Class III A combustible liquids are more ignitable; they have a flash point at or above 140°F (60 C) but below 200°F (93.3 C). Class III A combustible liquids are very similar to GHS Category 4 flammable liquids, which have a flash point above 140°F (60 C) up to 199.4°F (93 C).

Examples of Class III B combustible liquids include all cooking oils. The interesting thing about cooking oils is that cooks are generally less concerned about the flash point or the AIT than they are about the smoke point. The smoke point of a cooking oil is the temperature at which it begins to break down, releasing a black cloud of low molecular weight decomposition products, which give food a scorched, acrid flavor. For most cooking oils, the smoke point is ~160°F (~70 C) lower than the oil’s flash point.

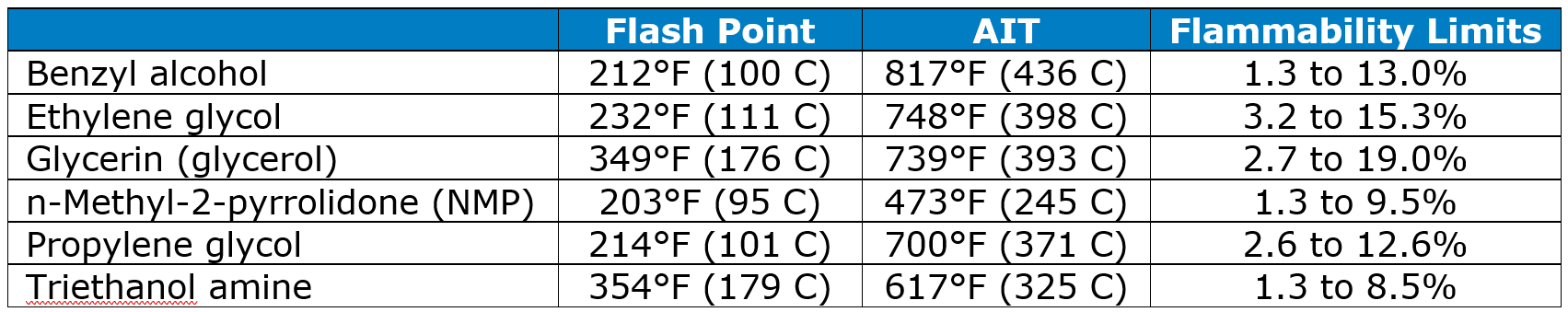

In the process industries, we’re more likely to deal with pure chemicals. Examples of Class III B combustible liquids that are pure chemicals are shown in the table below, along with their flash point, AIT, and flammability limits when mixed with air (from too lean to burn to too rich to burn).

Table. Examples of Class III B Combustible Liquids

Regulatory Requirements

The 2024 edition of NFPA 30, Flammable and Combustible Liquids Codes is the most current edition. While strongly encouraged and incorporated as enforceable code in some local jurisdictions, the regulation that all U.S. companies are compelled to follow is OSHA’s Flammable Liquids standard, 29 CFR 1910.106. The Flammable Liquids standard is largely unchanged since OSHA first adopted the 1969 Edition of the NFPA code back in 1974. The code and the standard share six concerns:

- Materials of construction

- Amounts

- Spacing

- Sources of ignition

- Venting

- Protection

An interesting point in the OSHA regulation is that a liquid with a flash point above 199.4°F (93 C), which are what NFPA calls a Class III B combustible liquid, is not regulated by OSHA. That is, EXCEPT for when “when it is heated for use to within 30°F (16.7 C) of its flash point.” Then it must be handled “in accordance with the requirements for a Category 4 flammable liquid” (what NFPA calls a Class III A combustible liquid).

When a Class III B combustible liquid is heated to within 30°F (16.7 C) of its flash point, understanding the regulatory requirements for handling that Class III B combustible liquid means understanding the regulatory requirements for handling Category 4 flammable liquids.

Storage (Amounts and Spacing)

While it is not uncommon to heat stored liquids, especially when they are very viscous or have a high melting point, it is rare to heat Class III B combustible liquids to within 30°F (16.7 C) of their flash points. When they are, however, the amount that can be stored outdoors is limited to 22,000 gallons (83,000 liters) per pile, and piles must be separated by at least 5 feet (1.5 meters).

The amount of Category 4 flammable liquids (Class III A combustible liquids) that can be stored indoors is 55,000 gallons (208,000 liters) per pile, and piles must be separated by at least 4 feet (1.2 meters).

There are more requirements in the standard that people should be aware of, but in reality, the limits for Category 4 flammable liquids are not really very limiting.

Hazardous (Classified) Locations (Sources of Ignition)

When it comes to ignition sources, the sources we worry about most are smoking and electrical equipment. As for smoking, don’t.

Flammable liquids prompt concern about whether Class I electrical equipment is required, and the extent that Division 1 and Division 2 boundaries extend. However, OSHA’s Flammable Liquid standard repeatedly states that:

“If only Category 4 flammable liquids are handled, then ordinary electrical equipment is satisfactory though care shall be used in locating electrical apparatus to prevent hot metal from falling into open equipment.” (29 CFR 1910.106(e)(7)(i)(c) for industrial plants, which include some chemical plants)

“For areas where only…Category 4 flammable liquids are stored or handled, the electrical equipment may be installed in accordance with the provisions of Subpart S [Electrical Safety] of this part, for ordinary locations.” (29 CFR 1910.106(f)(5)(i) for bulk plants, which include tank farms)

“If … Category 4 flammable liquids only are handled, then ordinary electrical equipment is satisfactory though care shall be used in locating electrical apparatus to prevent hot metal from falling into open equipment.” (29 CFR 1910.106(h)(7)(iii)(c) for processing plants, which contain chemical operations such as oxidation, reduction, halogenation, hydrogenation, alkylation, polymerization)

How does this square with NFPA 497, Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas? In 4.2.7.3, NFPA 497 states that “Class IIIB liquids [those with flash points above 93 C] seldom evolve enough vapors to form ignitable mixtures, even when heated, and they are seldom ignited by properly installed and maintained general purpose electrical equipment. A Class IIIB liquid will cool below its flash point very quickly when released. Therefore, area classification is seldom needed, and Class IIIB liquids are not included in Table 4.4.2.”

But what if Class IIIB combustible liquid were heated and treated as though it was a Category 4 flammable liquid (a Class IIIA combustible liquid)? NFPA 497 states in 4.2.7.2 that “Class IIIA liquids do not form ignitable mixtures with air at ambient temperatures unless heated above their flash points. Furthermore, the vapors cool rapidly in air and condense. Hence, the extent of the area requiring electrical classification will be very small or nonexistent.”

No, Kitchens are Not Class I, Division 1 Locations

Class III B combustible liquids can burn, so they should not be treated as though they are not harmless from the perspective of fire hazards. However, the hazards they pose are not so grave as to require classified electrical installations, or onerous restrictions when stored. And no, a grease fire in a commercial kitchen is not evidence that it needs to be wired as a Class I, Division 1 location.