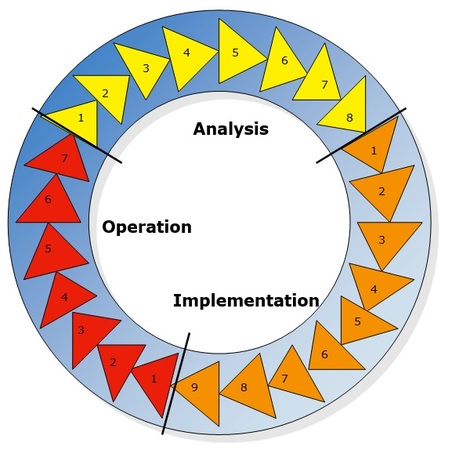

Safety Lifecycle

From Analysis through Operation, we provide the expertise to make your plant and processes safer.

We’re here to help you in all phases of the Safety Lifecycle. Please explore each of the section below for a brief description of the aspects of the safety lifecycle and the services we provide:

Analysis

Summary

Conclusions about whether a project will require a safety system or not cannot be drawn before there is a process design. The contributions of process design to a project are most intense in the earliest part of the project lifecycle. This includes conceptual review, process flow diagrams (PFDs) along with their Heat and Material Balances, and piping and instrument diagrams (P&IDs).

Bluefield Process Safety recognizes that operating companies usually do their own process design work. Process engineering is at the core of what an operating company does, and is usually the last piece to be outsourced. However, when assistance is required, the process consultants at Bluefield Process Safety can develop and prepare process design documents or confirm that existing process design documents accurately reflect the process.

Process safety begins with the initial concept of the project, where hazards are identified even as the process is synthesized. Typically, this hazard identification begins during preliminary process hazard analysis (PHA). Preliminary PHAs use simpler analysis techniques like “What If?” and “Checklist” techniques. Like all PHAs, preliminary PHAs should be conducted by a team that includes expertise in the technology of the process, the operation of the process, and the PHA methodology.

The detailed PHA that follows is typically a Hazard and Operability Review, or HazOp. The HazOp methodology is so commonly used, that in the minds of many, PHA and HazOp have become interchangeable terms, although the HazOp is just one of many PHA methodologies. A facilitator from Bluefield Process Safety can make your PHA as efficient and productive as possible, keeping things moving and focused on problem areas. The expertise of a facilitator from Bluefield Process Safety can keep your team on track, preventing your PHA from bogging down and squandering the time of your team members.

Dust Hazard Analysis, or DHA, is typically performed for industries that may create combustible dusts capable of cloud fire or explosions. Using National Fire Protection Agency codes on combustible dusts as a standard, Bluefield Process Safety can facilitate a DHA efficiently and thoroughly, providing recommendations to improve your current housekeeping and dust collection policies.

Hazards have the potential to cause harm, but it is risk assessment that quantifies that potential. Risk has two components: likelihood and consequence. Process safety consultants from Bluefield Process Safety can use their extensive experience with Offsite Consequence Analysis (OCA) and Quantitative Risk Analysis (QRA) to quantify consequences. Typically, you will find even greater value in Bluefield consultants’ experience facilitating Layers of Protection Analysis (LOPA) to quantify likelihood.

Knowing the risk of various hazards is of little value in itself. It is only in comparing those risks against your Risk Tolerance Criteria (RTC) that you know that a specific risk is too much or not. If you have corporate or plant risk policies, they may or may not be suitable for process design, or you may have no formal risk criteria at all.

Bluefield Process Safety does not decide what risk a company should assume, which would be presumptuous of any third party. However, Bluefield Process Safety routinely works with clients to translate existing risk policies into RTC suitable for design. Where risk policies don’t exist, Bluefield Process Safety can facilitate the process by which you establish your own RTC, using industry and government benchmarks.

Risk assessment may identify a need to add additional independent layers of protection (IPLs) to your project, in order to bring risks within your RTC. These IPLs may or may not be instrumented. Depending on the risk reduction required, instrumented IPLs may be control loops within a basic process control system (BPCS) or safety instrumented functions (SIFs) within a safety instrumented system (SIS). Non-instrumented IPLs can include both passive process components (dikes, blast walls, secondary containment) and active components (redundant equipment, relief valves).

The allocation of risk reduction to the optimum combination of instrumented and non-instrumented IPLs allows you to achieve required risk reduction at a minimum capital and operating costs. Bluefield consultants, steeped in both approaches, are not inclined to favor only one approach.

Definition of safety functions or IPLs, whether instrumented or non-instrumented, moves them beyond allocation to conceptual design.

For non-instrumented IPLs, this is a scope definition very similar to that of any process project. Bluefield Process Safety is able to prepare conceptual design definitions suited for project specification.

For a SIS, this consists of preparing a SIF List which includes causes and effects, as well as the required safety integrity level (SIL) of each SIF, with the required SIL being determined by a comparison of assessed risk with tolerable risk.

The project specification of an IPL is the basis of detailed engineering design. For non-instrumented IPLs, Bluefield Process Safety can prepare the more traditional project specification that mechanical, electrical and control, and structural engineers use to develop detailed engineering designs.

Of more specific interest when you intend to incorporate SIFs into your process, Bluefield Process Safety can lead the development of a safety requirements specification (SRS) that can then be used as the basis for equipment vendors to develop quotes and that comply with the requirements of the widely accepted SIS Standards, IEC 61511 and ISA S84-2004.

Bluefield Process Safety can also do the SIL verification calculations that assure that conceptual designs meet your risk reduction, or reliability, requirements. In particular, the SIS standards require the completion of PFD calculations to verify that risk reduction requirements are met. Bluefield Process Safety uses a combination of software tools and complex hand calculations following accepted methodologies to complete this work.

Implementation

During mechanical/electrical/structural detailed design, the engineering design team takes the process design and the SIS design and translates them into construction documents from which skids can be built and facilities can be constructed.

A plant cannot be built directly from P&IDs and an SRS. Bluefield Process Safety is ready to work with your engineers as they put together the plans and drawings your contractors need to build your process.

Software configuration translates control strategies implied in the P&IDs and safety strategies described in the SRS into computer programs that actually control your process. Good programmers, familiar with the requirements of the hardware you’ll be using, can make the difference between a facility that limps along and a facility that hums. Bluefield Process Safety is always delighted to work with your software configurers.

Fabricating equipment modules, control cabinets, and other skid-mounted components is best when done by vendors with well-equipped and spacious facilities, well-trained and motivated craftsmen, and a purchasing and management team that can stay on top of procurement and schedule. Equipment build is not a service that Bluefield Process Safety offers, but we always admire it when it is done well.

The time to catch issues with equipment modules, control cabinets, and other skid-mounted components is usually before it ships to the construction site. Factory acceptance testing allows you to take advantage of the controlled environment of the shop where your equipment was built, to access the familiarity and skills of the personnel that put it together to resolve any issues, and to be confident that it is fully functional and assembled from standard parts before it arrives at the site. When selecting a vendor to fabricate your skid-mounted equipment, be sure to consider their ability to accommodate your need for factory acceptance testing.

Construction and installation of a project can fall anywhere in the spectrum from totally “stick-built” to totally modular construction. At its most extreme, totally modular construction consists of receiving everything on skids, flanging them up, bolting them together, and plugging them in. On the other hand, totally stick-built construction relies completely on craftsmen in the field to put everything together from basic components. Both approaches have advantages and disadvantages, so you will want to make sure that your contractor is able to accommodate your construction strategy, whether for an entire new plant or for the retrofit of an existing plant to include a new SIS.

After construction and installation, but before any process materials are introduced into the system, it is important to test how the entire process functions and how all of the component pieces of equipment and instrumentation interact with one another. Each SAT is unique to each project, and is typically carried out by a team drawn from construction contractor, equipment vendor representatives, and plant operations and maintenance.

Validation of a safety instrumented system ensures the SIS and each safety instrumented function perform the way they were designed to perform. The process of validation combines field tests, calibration, and simulations to confirm that SIFs and the SIS work correctly. A validation plan depends on both the system requirements and the characteristics of the individual components. Skilled instrument mechanics are an important part of validation. Validation should be carried out after the process and control systems have been installed but prior to the introduction of any process or utility hazards.

Training appears in the project safety lifecycle twice: in the project implementation phase and in the operation phase. A safe operation depends on operation and maintenance personnel understanding their process and its safety features before it ever starts up, and on ongoing training in variety of topics. Bluefield Process Safety has developed a range of courses to meet these training needs, and is able to develop and conduct specific training as is required.

The pre-startup safety review (PSSR) is not just a requirement before introducing chemicals into a process covered by the Process Safety Management (PSM) Standard, but the best practice for starting any process. Bluefield Process Safety can assist in planning a PSSR and where needed, can participate in conducting a PSSR.

Operation

Operation is core to the plant and represents the phase of the safety lifecycle where the plant spends most of its time. With a well designed process, good management, a dedicated operating team, and a little luck, a SIS will sit quietly in the background, never called upon to do a thing. Nonethless, the operating team needs to remain ever mindful of the potential for deviations and how all of the risk reduction measures in the plant work together to keep them safe.

Training appears in the project safety lifecycle twice: in the project implementation phase and in the operation phase. A safe operation depends on operation and maintenance personnel understanding their process and its safety features before it ever starts up, and on ongoing training in variety of topics. Bluefield Process Safety has developed a range of courses to meet these training needs, and is able to develop and conduct specific training as is required.

Similar to validation, proof testing is the defined procedure of confirming that the SIS and its SIFs are functioning correctly and as they were designed. Each SIF must be tested in its entirety, either as a complete loop or component-by-component. When proof testing happens by component, separate components of the same control loop may be tested at different times and at different intervals.

Proof test and proof test intervals are established at the time the SIS is specified. Probability of failure on demand for each SIF depends not only on the quality of the components used, but on the proof test interval. Once the proof test is designed and the interval established, it typically falls to intrument maintenance staff, either from the plant or the instrument vendors, to perform the proof testing. Bluefield Process Safety does not include instrument mechanics on its staff that can perform proof tests, but is certainly able to review proof testing procedures to assure they cover the entire loop, and to do calculations necessary to determine appropriate proof test intervals.

Inspection is the fairly simple act of observing whether components in the plant, particularly components of an SIS, are in good shape. They may be still working and able to pass a proof test, but be suffering from fatigue, corrosion, loose or missing parts, or other conditions that compromise the integrity of the process. Inspection alerts the plant to problems without waiting for an actual failure.

Inspections are not complicated, but they need to be done and done by personnel who know what they are doing and what they are looking for. Bluefield Process Safety has developed inspection procedures for use by clients or by Bluefield staff to conduct process inspections.

Whatever combination of preventative, predictive, and corrective maintenance is appropriate for your facility, good maintenance is critical to the ongoing safety of an operation. Whether a component is covered under the Mechanical Integrity provisions of the PSM standard or not, proper maintenance procedures and effective maintenance staff keep a process functioning efficiently. Failure rate calculations all assume that a discovered failure will be repaired promptly; a neglected failure quickly compromises any assessment of the safety of a facility.

MOC is the process of identifying, analyzing, and tracking any adjustments to the process or equipment. OSHA’s PSM standard requires plants to monitor any change to the process that is not a “replacement in kind” and how it affects the hazards, production, operations, and safety of the process. Once these effects are identified, the standard also requires the plant to update any procedures, safety functions, hazard analyses, or other documents as appropriate. MOC has become such a standardized practice that most plants should have a system in place. Some facilities have found it useful to have Bluefield Process Safety review their MOC policies and procedures to assure they comply with regulatory requirements and the specific requirements of safety instrumented systems.

As the exit from an otherwise eternal safety lifecycle, decommissioning is the process of safely shutting down the process for the final time and then safely deconstructing and disposing of the equipment. Decommissioning is often overlooked when the process is designed, and procedures are typically developed near the end of the process’s useful life; however, decommissioning is an important element of safe process management. The gravest concern is that any decommissioning activity not interfere with or inadvertently impact other processes that are remaining active. Careful consideration must be taken to ensure that utilities or safety equipment for processes still in use are not damaged or removed along with the decommissioned process.

*Services provided by Bluefield Process Safety, LLC.

Training Courses

Training appears in the project safety lifecycle twice: in the project implementation phase and in the operation phase. A safe operation depends on operation and maintenance personnel understanding their process and its safety features before it ever starts up, and on ongoing training in a variety of topics. Bluefield Process Safety has developed a range of courses to meet these training needs and is able to develop and conduct specific training as is required. Bluefield Process Safety will train your staff on-site and provide certificates of completion. Please contact Bluefield Process Safety for pricing and scheduling of a training session. We offer training sessions both in person as well as via teleconference.

Summary

This 10 hour course was designed by OSHA for managers, engineers, technicians, mechanics, operators, and other personnel that work in any manufacturing facility. It includes required core topics, elective topics, and additional topics you can choose that are especially suited to your organization. It can be scheduled to be completed in one very long day, or more typically, over two days, or even in a series of one-hour sessions scheduled over the course of time (up to six months).

This course establishes a familiarity with the OSHA standards that are most commonly cited and covers the key requirements of OSHA compliance.

Students receive a manual for reference. OSHA provides certification in the form of wallet cards that Bluefield Process Safety will mail to each participant who successfully completes the course.

Prerequisites

N/A

Outline

Core Topics (seven hours total)

Introduction to the OSH Act and OSHA (2 hours)

Walking and Working Surfaces

Exit Routes, Emergency Action Plans, Fire Prevention Plans

Personal Protective Equipment

Electrical

Hazard Communication

Elective Topics (at least two topics for an hour each)

Hazardous Materials (PSM and HazWOpER)

Machine Guarding

Bloodborne Pathogens

Ergonomics

Additional Topics (these or elective topics to complete 10 hours)

HazOps

Lockout/Tagout

Permit Required Confined Space Entry

Incident Investigation

Hazard Identification and Risk Assessment

Safety Culture and Ethics

Product Liability and Safety

Summary

This course is intended for any personnel who work in the chemical manufacturing industry.

This instructor-led course is a high-level overview that covers the fundamentals of recognizing hazards in the workplace, focusing on those in the chemical manufacturing industry. Participants will come away with an understanding of the hazards presented by manufacturing processes, the principles of fires and explosions, the risks associated with exposure to harmful substances, and typical causes to protect against.

We currently offer a 2-hour course and a 4-hour course.

Prerequisites

N/A

Outline

Manufacturing Process Hazards

Workplace Hazards

Process Hazards

Fires and Explosions

About Fires and Explosions

Estimating the Severity of Fires and Explosions

Exposure to Harmful Substances and Environments

Electricity

Asphyxiation

Toxic Exposure

Estimating the Severity of Toxic Releases

Typical Causes of Process Incidents

Summary

This course is intended for any personnel who want exposure to the Process Hazard Analysis (PHA) methodology.

This 1-hour, instructor-led course is a high-level overview of the PHA process that goes into the basics of hazard awareness and the methods available. This is a perfect beginner’s course for introducing participants to the concept of a PHA.

Prerequisites

N/A

Outline

Hazard Identification

PHA Methodologies

HazOps

Summary

This course is intended for any safety personnel who work with or around Flammable Liquids.

This 2-hour, instructor-led course is a focused discussion of the hazards associated with flammable liquids. The NFPA 30 standard will be referenced and used as a guide throughout the course. Participants will leave the course with the knowledge to correctly identify and classify flammable liquids and an understanding of the best methods of protecting against the hazards associated with their use and storage.

Prerequisites

N/A

Outline

History and Background of NFPA 30

Flammable Liquid Classifications

Storage in Containers

Storage in Tanks

Operations

Sources of Ignition

Protection

Summary

This course is intended for process safety personnel who participate in or lead incident investigation teams. This course goes into more depth than the incident investigation awareness training that may be included as part of OHSA 10 Hour Training.

This instructor-led course uses a combination of lecture, discussion, and hands-on exercises to teach the skills necessary to effectively function as the leader of an incident investigation committee and to analyze incidents in a systematic manner that assures improvement of the process that generated the incident. Participants will leave the course ready and able to complete and lead incident investigations and improve overall safety.

We currently offer a 2-hour course and an 8-hour course.

Prerequisites

None

Outline

ESH Management Theory

Human Behavior

The Incident Analysis Process

Interviewing Techniques

Photography

Incident Statements

Summary

This course is intended for any personnel who are part of the Management of Change (MOC) process.

This 2-hour, instructor led course uses a combination of lecture, discussion, and hands-on exercises to educate participants on the MOC process, its history and requirements. Exercises in this course focus on replacements-in-kind. Discussion will focus on facility specific examples, ambiguity in MOC, and obstacles to implementing MOC.

Prerequisites

None

Outline

Management of Change

Replacement-in-kind

Emergency Changes

Summary

This course is for professionals responsible for implementing process safety in a technical or industrial environment, including those responsible for specifying and implementing Safety Instrumented Systems (SIS).

This instructor-led course covers the complete Safety Lifecycle. It is also an excellent introduction for anyone seeking a better understanding of the safety lifecycle. The IEC 61511 standard will be referenced and used as a guide through the analysis, realization, and operation of an SIS. Exercises will include process hazard analysis, SIL determination, SRS definition, and SIF design.

We currently offer a 1-hour course and a 4-hour course.

Prerequisites

None

Outline

Introduction to the Safety Lifecycle

Regulations and Standards

Process Safety Information

Hazard Identification

Tolerable Risk

Risk Analysis

Safety Integrity Levels

Safety Instrumented Systems

Safety Requirements Specifications

Implementation

Validation

Pre Startup Safety Review

Operations and Maintenance

Proof Testing and Inspections

Functional Safety Management

Quality Systems and Documentation

Summary

Bluefield Process Safety has developed a series of courses that go into different levels of detail about the process safety management standards. One is a one-hour overview, providing general awareness training for personnel that works in a facility with processes covered by OSHA’s Process Safety Management (PSM) standard: managers, engineers, technicians, mechanics, operators, and others. The two-hour description is intended for the same audience but goes beyond a general awareness to include a description of each of the 14 elements of PSM.

The four-hour and eight-hour courses provide increasing detail on the standard and guidance on how to comply with the standard, and the 16-hour course also goes into more detail about the nuances of establishing process boundaries and the differences between OSHA’s PSM standard and the EPA’s Risk Management Planning (RMP) rule.

Each participant receives electronic copies of the presentation material and certificate reflecting the Professional Development Hours completed.

Prerequisites

None

Outlines

1 hour Course:

An Overview of the PSM Standard

2 hour Course:

Background and History of PSM

Covered Processes

The Fourteen Elements

4 hour Course:

Background and History of PSM

Covered Processes and Their Boundaries

The Hard Elements

break or lunch

The Other 11 Elements

Traps and Pitfalls

8 hour Course:

Introductions and Safety Moment

Background and History of the PSM and RMP Standards

Covered Processes and Their Boundaries

Differences Between PSM and RMP

break

Employee Participation

Process Safety Information

Process Hazard Analysis

lunch

Operating Procedures

Training

Contractors

Hot Work Permits

Mechanical Integrity

break

Management of Change

Pre-Startup Safety Review

Emergency Planning and Response

Compliance Audits

Trade Secrets

16-Hour Course:

Day 1

Introductions and Safety Moment

Background and History of the PSM and RMP Standards

Covered Processes Under PSM

Boundaries of Covered Process

break

Differences Between PSM and RMP

Employee Participation

lunch

Process Safety Information

break

Process Hazard Analysis

Day 2

Operating Procedures

Training

Contractors

Hot Work Permits

break

Mechanical Integrity

lunch

Management of Change

Pre-Startup Safety Review

Emergency Planning and Response

break

Compliance Audits

Trade Secrets

Common Citations Under the PSM Standard

Summary

This course is intended for any safety personnel who work with a PSM or RMP covered process.

This 1-hour, instructor led course will educate on the requirements for processes governed by OSHA’s PSM standard and the EPA’s RMP rule. Participants will leave the course with an understanding of how to recognize if a process is covered and how to determine the boundaries of their covered processes.

Prerequisites

N/A

Outline

Covered Applications

Toxic and Reactive Chemicals

Flammables

Exceptions and Exemptions

Summary

This is a 4-hour course. It is intended for personnel that are responsible for ensuring OSHA’s Process Safety Management standard is being effectively and fully enforced at their facility.

The course refreshes workers on the OSHA PSM standard and its 14 elements before applying the standard hands-on to practical application scenarios and instructor-led review of company safety procedures. Each participant receives copies of the presentation material, example scenarios, and accompanying notes. With sufficient time to prepare, the example scenarios will be adapted to incorporate the facilities own PSM-covered process and documentation.

Prerequisites

Basic awareness of the OSHA PSM standard (TC-204 or equivalent)

Outline

The Purpose of Compliance Audits

The PSM Standard

How the RMP Rule Differs

The Audit Team

The Audit Procedure

Findings, Recommendations, and Suggestions

The Audit Report

Summary

This is a 4-hour course intended primarily for inexperienced engineers and technicians with little or no experience with process flow diagrams and piping and instrument diagrams. It helps organizations avoid the costs and delays that result from a misunderstanding of drawings. It exposes participants to all of the elements of PFDs and P&IDs and teaches participants how to read and interpret these fundamental drawings.

Participants receive copies of the presentation.

Prerequisites

N/A

Outline

Introduction to Flow Diagrams–BFDs, PFDs, EFDs

Instrument Symbols

Electrical Equipment

Process Equipment Symbols

Piping

Lead Sheets

Issuing P&IDs

Drawing Interpretation

Summary

This is a very full 8-hour course for process design engineers responsible for preparing piping and instrument diagrams as part of front-end engineering design packages.

This is not a course on drafting standards. Instead, it is intended for process engineers who must start with a clean sheet of paper and prepare P&IDs, but who do not have a mentor in their organization to guide their efforts. The course includes exercises that are completed individually and in groups.

Prerequisites

Experience or training reading P&IDs (TC-221 or equivalent).

Outline

Flow Diagrams

Introduction to Flow Diagrams

Lead Sheets

Electrical and Instrument Symbols

Process Equipment Symbols

Piping

Drawing Interpretation Exercise

Reviewing, Revising, and Issuing Flow Diagrams

Review PFDs

Electrical and Instrument Review of P&IDs

Reviewing Equipment and Lines on P&IDs

Overall P&ID Reviews

Making Revisions and Management of Change

Issuing Drawings

Cost of Revisions

P&ID Review Exercise

Preparing Process Flow Diagrams

Before Starting

Laying Out PFDs

PFD Streams

Material Balances

Heat Balances

Material and Heat Balance Exercise

Preparing Piping and Instrument Diagrams

Before Starting

Laying Out P&IDs

Piping and Equipment

Electrical and Instrumentation

Operating and Safety Considerations

Equipment Data

P&ID Preparation Exercise

Summary

This 2-hour course is on Hazardous (Classified) Locations for engineers that are familiar with the need for “electrical classification” drawings when flammable gases and vapors are used, or when combustible dusts are handled, but want more understanding on how to classify hazardous locations.

Prerequisites

N/A

Outline

Nomenclature

Classes vs. Zones

Classes, Divisions, and Groups

Interchangeability – Classes vs. Groups

Standards

Bubble Diagrams

Adequate Ventilation

Open vs. Enclosed

Unclassified Locations

Common OSHA Citations

Acceptable Electrical Equipment

Fork Trucks

Summary

This course is for process safety personnel who have participated in Process Hazards Analysis and want to learn how to facilitate a PHA.

This is an 8-hour hands-on, instructor-led course. The course includes a review of several PHA techniques (including HazOp, What If, Checklist), and gives guidance on when each technique may be preferred. It then focuses on the PHA technique most widely used in the chemical process industries, the HazOp. The course addresses how to prepare for a PHA, how to identify PHA nodes on a P&ID, how to conduct a PHA (including tips on keeping the team moving and dealing with disruptive team members), and the format for compiling and reporting the results of the PHA. The course concludes with a discussion of how to estimate the time and cost of a HazOp and other PHAs.

Prerequisites

Experience participating in at least one PHA (recommended).

Outline

Introduction

PHA Background

Regulatory Compliance

Techniques for Conducting a PHA

What If

Checklist

HazOp

Other Requirements

Preparing for a PHA

Defining Nodes

Team Selection

Conducting a PHA

Guide Words

Working with a Scribe

Compiling a PHA

Reporting Format

Summary

This course is intended for any personnel who participate in Procedural HazOps.

This 2-hour, instructor-led course uses a combination of lecture and exercises to educate on Procedural HazOps. Participants will leave the course with an understanding of when to perform a Procedural HazOp, and how to plan for, prepare, and conduct one.

Prerequisites

A basic understanding of the PHA methodology is preferred, (i.e. TC-104)

Outline

Procedural HazOp Overview

Planning

Preparation

Conducting the HazOP

Follow Up

Summary

This is a 1-hour course on Risk Tolerance Criteria. Participants will gain understanding of the components of risk, the amount of risk tolerated in society, and the amount of risk tolerated in organizations and industry (specifically the process industry). Participants will also engage in practical exercises to allow them to set risk tolerance criteria that are useful as a design basis.

Prerequisites

N/A

Outline

Hazards vs. Consequences vs. Risk

Likelihood and Consequence Analysis

Quantification of Risk

Risk Benchmarking

ALARP

Prevention vs. mitigation

SIL overview

Optional Topics:

Environmental Risks

Community Risks

Commercial Risks

Summary

This 8-hour course is for process safety personnel who quantify the consequences of safety incidents for the purposes of quantifying risk off the plant site.

The US EPA’s guidance documents on off-site consequence analysis (OCA) describe how the consequence component of risk should be determined for both worst cases and alternative cases. While other tools are available, the EPA OCA guidance is widely used, and the basis of comparison for most discussions with the public. This one-day course explains the theory behind these EPA-approved techniques, and trains participants in their use through a combination of lecture, discussion, and hands-on exercises. The course wraps up with an exercise in the use of the EPA software, RMP*Comp, and a review of the requirements for an EPA Risk Management Plan.

Prerequisites

Experience assessing consequence (i.e. TC-235)

Outline

Toxic Gas Releases

Liquid Spill and Vaporization

Vapor Cloud Explosions

BLEVE (Boiling Liquid Expanding Vapor Explosions)

Pool Fires

Jet Fires

RMP*Comp

EPA Risk Management Plans

Summary

This is a course to train process safety personnel to participate in and facilitate LOPAs for the purposes of estimating the likelihood component of risk.

This LOPA technique is endorsed by the Center for Chemical Process Safety and widely accepted in the process industries. This course prepares participants to develop scenarios, evaluate safeguards as potential layers of protection, and use appropriate probabilities to calculate frequency, or likelihood, of safety critical scenarios.

Participants receive a copy of the Bluefield Process Safety LOPA tool and training to calibrate it to their organization’s own risk tolerance criteria.

We currently offer a 2-hour overview course and a 4-hour full course.

Prerequisites

N/A

Outline

Understanding Layers of Protection Analysis

Introduction

Layers of Protection

Risk

Overview of LOPA

Event Tree Analysis

Elements of LOPA

Limitations of LOPA

Using Layers of Protection Analysis

Initiating Events

Enabling Conditions

IPLs—Rules

IPLs—Types

Calculations

SIL Assignment

Special Topics

Multiple Functions

Operator Response

Plant Operations as Tests

Demand

Bluefield Worksheet

Summary

This course applies to anyone within the process industry that is involved in establishing or assigning Safety Integrity Levels. Participants need not be the engineers or supervisors responsible for verifying SIL effectiveness.

Course material will review risk and tolerable risk, discuss and evaluate tools to compare risk with risk tolerance criteria, practice calibration of tools to applicable criteria and process variables at the client company, and discuss how to evaluate results from the tools to achieve SIL values

We currently offer a 1-hour overview course and 4-hour full course.

Prerequisites

Competent understanding of components of risk and tolerable risk criteria.

Outline

Review of Assessing Risk

Likelihood and Consequence Components

Tolerable Risk Criteria

Reference Data

Tools for Calculating and Comparing Risk

Calibrating Tools to Established Tolerable Risk Criteria

Summary

This 4-hour course introduces participants to Independent Layers of Protection and helps them to understand different considerations and techniques required to effectively design and take credit for IPLs.

This is a hands-on, instructor-led course that uses a combination of lecture, class discussion, and exercises to teach the material. Participants will work individually and in groups to develop and evaluate different functions. Participants will receive copies of the presentation and supplemental notes.

Prerequisites

Basic knowledge of process safety

Outline

Non-Instrumented IPLs

Standard IPLs

PPE

Instrumented IPLs and SIFs

BPCS vs. SIS

SIFs and SILs

Architecture

SIFs – General Design Issues

The basic SIF

DTT vs. ETT

Proof testing

Response time

Bypassing

SIFs with Multiple Devices

Multiple Sensors

Multiple Final Control Elements

Grouping

Sharing Devices

SIFs – Specific Design Issues

Pump and Discharge

Double Block and Bleed

Unit Isolate and Bypass

Valve Position Switches

Summary

This 4-hour course introduces participants to the Safety Instrumented Functions and helps them to understand different considerations and techniques required to effectively design SIFs.

This is a hands-on, instructor-led course that uses a combination of lecture, class discussion, and exercises to teach the material. Participants will work individually and in groups to develop and evaluate different functions. Participants will receive copies of the presentation and supplemental notes.

Prerequisites

Basic knowledge of safety instrumented systems (TC-201 or equivalent).

Outline

Introduction

Background

Safety Instrumented Functions

General Design Issues

Basic SIF Design

Proof Testing

Response Time

SIF Bypasses

Multiple Devices

Multiple Sensors

Multiple FCE(1oo2)

Grouping

Sharing Devices

Specific Design Issues

Pump and Discharge

Double Block and Bleed

Unit Isolate and Bypass

Valve Position Switches

Summary

This course is intended for any safety personnel who with or around fuel-fired processes.

This 1-hour, instructor-led course is a focused discussion of Burner Management Systems (BMSs). Participants will leave the course with an understanding of the hazards associated with fuel-fired processes, as well as the purpose of, components of and standards surrounding BMSs.

Prerequisites

An understanding of Independent Layers of Protection and their role in risk reduction is preferred (i.e. TC-237)

Outline

Purpose of BMSs

Associated Deviations and Hazards

BMS Components

BMS Standards

Development and Compliance

Summary

This 8-hour course introduces participants to Pressure Relief Design and helps them to understand different considerations and techniques required to effectively select the proper relief equipment.

This is a hands-on, instructor-led course that uses a combination of lecture, class discussion, and exercises to teach the material. Participants will work individually and in groups to develop and evaluate different functions. Participants will receive copies of the presentation and supplemental notes.

Prerequisites

Basic understanding of Process Hazard Analysis (i.e. TC-104), ability to understand and perform engineering related calculations.

Outline

Introduction

Background

Safety Instrumented Functions

General Design Issues

Basic SIF Design

Proof Testing

Response Time

SIF Bypasses

Multiple Devices

Multiple Sensors

Multiple Final Control Elements

Grouping

Sharing Devices

Specific Design Issues

Pump and Discharge

Double Block and Bleed

Unit Isolate and Bypass

Valve Position Switches

Summary

This 4-hour course is intended for all process industry professionals who are asked to verify or modify Safety Integrity Levels or who audit Safety Instrumented Systems. Participants review math and theory involved in SIL establishment, then learn to use industry software to validate and audit established SILs.

Prerequisites

Experience with Safety Instrumented Systems and knowledge about SILs.

Outline

Standards

Modeling SIFs

PFD and PFDAVG Equations

Verification Software